Understanding Air Compressor Types

Compressed air is often called the "fourth utility" when applied to industrial operations. However, unlike water, gas and electricity the consumer is also typically the producer. Becoming your own compressed air utility provider is as simple as buying an air compressor and installing the air lines and associated support equipment.

One of the most important parts of producing compressed air is selecting the appropriate type of compressor for the application. Operators have essentially three types of equipment to choose from in fulfilling their compressed air needs, with types further divided into options that include oil-flooded or oil-free, water-cooled or air-cooled, and single-stage or multistage.

With those varieties in mind, the three basic types of air compressors are:

1. Reciprocating

For most people the principles of operation behind a reciprocating compressor are the easiest to understand. Also commonly referred to as a positive displacement compressor, a reciprocating compressor takes in a volume of air and, via a piston connected to a crankshaft, forces that initial volume of air into a smaller volume.

Reciprocating air compressors cover a broad range of output capacity. They are typically found in applications from 1 horsepower (hp) to more than 600 hp. The practical limit for a single stage of reciprocating compressors is typically considered to be 5 to 6 ratios. That is, if intake air is considered to be about 15 PSI(a) the discharge limit from a single stage is about 85 PSI(a). To achieve higher discharge pressures the process is simply repeated in a second compressor piped in series with the first to achieve two-stages of compression.

One advantage of a reciprocating compressor arises from its push-pull action. Compression can be configured to take place on one or both sides of the piston. If only one side of the piston is performing the compression, the process is referred to as single acting. If both sides of the piston are used, the process is referred to as double acting.

To ensure that the highest efficiency of compression is achieved an effective seal between the sliding piston and stationary cylinder is required. Although there are commercially available oil-free reciprocating compressors, it is more typical to see lubricated (also referred to as oil-flooded) machines. Introducing lubricating oil into the cylinder reduces the wear between the piston and cylinder wall but has the undesirable effect of mixing and carrying over into the compressed air stream. As a result, if the process using the air is not tolerant of the presence of lubricant in the air, a downstream separator is required to remove the oil from the air stream. Typically, oil separators are sized and selected based upon the end use of the air. That end-use dictates the oil removal rate and efficiency.

- Benefit - The primary benefit of reciprocating compressors is their simplicity and initial low cost.

- Drawback - The drawback is the frequency of piston and cylinder maintenance and the work involved to replace these parts.

From this perspective, compressor availability must be considered. In the case of oil lubricated machines, the significant drawback of the additional cost for oil separation systems and maintenance of those systems to produce air quality acceptable for the required process must be calculated into cost of ownership.

Due to the relatively harsh nature of their inherent operating characteristics reciprocating compressors often require more substantial foundations than the other two types of equipment.

Reciprocating compressors that feature outputs from 40 CFM at 100 PSI to 110 CFM at 150 PSI will start around $4,000 to $10,000, with midrange models available for $20,000 to $50,000. Large industrial-grade machines will extend beyond $100,000.

2. Rotary Screw

Although not as obvious as reciprocating compressors, rotary screw compressors are also positive displacement compressors. Compression is achieved via the meshing of two helically cut rotor profiles. One rotor is cut as a male profile, and the other as a female profile. These two rotors spin in opposite direction. For the oil flooded configuration, the male rotor drives the female rotor. And for the oil free configuration, the rotors are kept in precise synchronization via a timing gear.

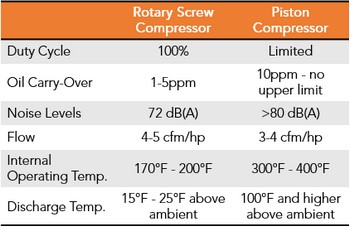

A quick comparison of rotary screw and reciprocating piston compressor stats. For more on this topic, explore this free whitepaper provided by Kaeser.

Through an intake port a charge of air is trapped between the meshing lobes. This trapped volume is squeezed along the axis of the rotor into a decreased volume until it reaches the exit port where it is discharged.

Volume is dictated by the physical size of the rotors as well as the depth of the cut in the pockets. The ratio of compression is governed by the length of the rotor which sets the amount of compression that takes place.

Rotary screw compressors are found in applications ranging from 30 to 350 hp. Typically used in plant air applications for 125 to 150 PSI(g), the practical discharge pressure limit for rotary screw air compressors is considered to be 250 PSI(g).

Although usually configured as single stage machines, rotary screw compressors may also be configured for multiple stages of compression. This can be accomplished with multiple screws within a single body, but can also be carried out in two separate bodies.

Similar to reciprocating compressors, if oil contamination is not desirable or permissible in the process, a downstream separator is required following the compressor. The same care described above for reciprocating compressors and the removal of contaminating lubricant from the process air is applicable to oil flooded screw compressors.

Oil free rotary screw compressors are also available. They accomplish the sealing between the rotor bodies and outer casing by means of precision machined sealing strips or abradable coating on both the male and female rotors. The wear characteristics of these sealing mechanisms determine the rate of performance deterioration that the compressor will experience over time.

- Benefit - The primary benefit of rotary screw air compressors is the initial low cost.

- Drawback - The drawback is the frequency of maintenance which often entails the complete replacement or overhaul of the rotors or complete air-end. Also, in the case of oil lubricated machines the penalty cost of equipment, maintenance and power for the removal of oil from the compressed air stream can also be viewed as detrimental.

As with reciprocating compressors, rotary screw models also feature the same basic price points, starting around $4,000 to $9,000, with midrange models available for $18,000 to $55,000. Large industrial-grade compressors extend beyond $100,000.

3. Centrifugal

While centrifugal compressors accomplish the same results as the previously described compressor types, they go about it in an entirely different way. Whereas reciprocating and screw compressors compress air by squeezing the air from a large volume into a smaller one, centrifugal compressors raise pressure by increasing the air's velocity. For this reason, centrifugal compressors are referred to as dynamic compressors.

Centrifugal compressors raise the pressure of air by imparting velocity, using a rotating impeller, and converting it to pressure. Each stage of compression in a centrifugal compressor consists of an impeller which rotates and a stationary inlet and discharge section. Air is directed into the "eye" of the spinning impeller through the inlet. The impeller imparts velocity to the air and discharges it into the diffuser where the velocity is converted to pressure.

Each stage of compression can achieve approximately 2.2 up to 3.0 ratios in air service. Due to the heat of compression, interstage cooling is required and can be accomplished through air-to-air or, more commonly, water-to-air cooling.

Centrifugal compressors are oil free. The air flow path and the oil system are independent, separated by seals and an atmospheric air space. Any lubricant required for the bearings or other mechanical components is sealed off from the air stream. This feature has the benefit of not requiring any downstream separation. Centrifugal compressors are ideally suited to processes where uncontaminated air is required for the application.

- Benefit - Centrifugal compressors are recognized for their ability to operate for long periods without required maintenance. They have a minimum number of moving parts, and do not rely on contact between parts to accomplish the compression process. A unique advantage of centrifugal compressors due to their dynamic nature is the lack of pressure pulsations. This makes them inherently quieter than their positive displacement counterparts and also results in smoother operation.

- Drawback - Only two stages are permissible. They also feature a larger frontal design to accommodate the airflow when compared to other varieties.

Overall, centrifugal compressors run at very low vibration levels which minimize the foundation requirements and associated piping supports. Pulsation bottles or receiver tanks are not required downstream of centrifugal compressors as is the case with positive displacement compressors. The result is that the installation cost for centrifugal compressors in lower than positive displacement compressors.

Costs range from $2,900 for a two-stage 10 hp model to $8,900 for a four-cylinder, 25 hp, two-stage electric model.

Summary and cost factoring

It's important to evaluate your specific application to determine the best type of compressor to be used. The most accurate method is to calculate the lifecycle cost of the machine. In this calculation, the key factors will be:

- Equipment cost

- Operating efficiency (power consumption)

- Installation cost

- Maintenance cost

If an oil-flooded compressor is being considered, the oil removal system and cost of maintaining the proper filtration must also be included. For a realistic comparison, a total life of 10 years would be a minimum.

Ready to Compare Air Compressors Price Quotes?