Leveraging Big Data to Drive Analytics at the Speed of Manufacturing

Big Data is a term on the lips of many in the IT world today, and for good reason. Along with other impending and rapidly evolving tech trends like cloud computing, mobile capabilities, and the Internet of Things (IoT), Big Data is poised to transform both the consumer and industrial world across the board.

But with this onslaught of data comes new challenges facing companies. More than just the volume of the data involved, the structure and variety of information leaves manufacturers with the difficulty of contextualization and deriving real, actionable intelligence. But today's leading organizations are finding ways to capture and analyze Big Data in a way that is driving real-time value in operations: by leveraging next-generation software solutions.

In this article, we'll dive deeper into some of the main challenges around Big Data, examine how leading manufacturers are approaching it today, and provide some recommendations for those companies looking to gain Big Data capabilities.

Big Data: What's in a Name?

At a high level, the term "Big Data" can be a bit of a misnomer -- it's about more than just size. The challenge for most manufacturers doesn't reside in data collection (most organizations have the IT infrastructure to handle this). But as we've discussed many times in the past, data for data's sake -- without proper contextualization -- is of limited value.

The challenge for companies is in translating and contextualizing data into actionable intelligence. Though many organizations have myriad solutions in place for monitoring, analyzing, and interpreting data , those that are in place generally don't have the capability to handle today's Big Data.

Today's Big Data analytics solutions provide manufacturing professionals with next-generation statistical analysis and visualization tools designed to handle massive sets of data -- both structured and unstructured.

Categorizing Big Data

More than just size, Big Data involves a grouping of structured and unstructured data coming at a velocity, variety, and volume that traditional solutions cannot process. To break down the categorization further:

- Structured data: Data that generally has a set of predetermined parameters or fixed fields. It's the data most typically stored in relational databases or spreadsheets.

- Unstructured data: This is data that may not have any predefined parameters or fixed fields and, subsequently, there is no data model.

- Velocity: This refers to the speed at which data is generated. It's generally real-time, time-sensitive streaming data.

- Variety: Each data record may include varied forms of structured and unstructured data, unpredictable data set sizes and unpredictable rates of exchange.

- Volume: This refers to the size of data sets, with transactions ranging from terabytes up to petabytes.

There are a number of technologies and trends within the manufacturing sphere that are contributing to this explosion of data, including advancements in the Internet of Things (IoT) and the Cloud.

The Role of Big Data Analytics

Technology advancements have evolved to a point that these previously unusable data streams are being harnessed to drive real intelligence. Today's Big Data analytics capabilities are designed to expose and contextualize these correlations between the aforementioned massive and unusually complicated data sets. Many of them incorporate predictive modeling and other preconfigured algorithms within solutions, and can play an important role in transforming disconnected manufacturing information sources into something consumable and useful for manufacturing professionals.

Another important consideration of today's solutions is how they are architected to conform to different user needs. Role-based dashboards are prominent to give actionable information to different levels of personnel. Though there are myriad ways Big Data can be leveraged today in a manufacturing environment, some of the key areas we see at LNS Research are:

- Correlating performance metrics across multiple plants

- Better understanding performance of the supplier network

- Servicing and supporting customer requirements faster

- Performing predictive modeling of manufacturing data

- Delivering real-time alerts based on manufacturing data

Event Processing: Accelerating Decision Making

As touched upon, most manufacturers have experience in collecting large amounts of data for continuous improvement insight; however, the speed at which manufacturing is moving today, when combined with the adoption of next-generation solutions, is increasing the number of events and the speed at which data-backed decisions need to be made. Connecting Big Data analytics with this event processing will be a key capability in allowing manufacturers to create and send real-time alerts and accelerate decision making.

By connecting Big Data analytics and event processing, incoming data will be automatically contextualized and routed to relevant roles from the shop floor all the way up through the C-suite.

Technology Adoption Trends

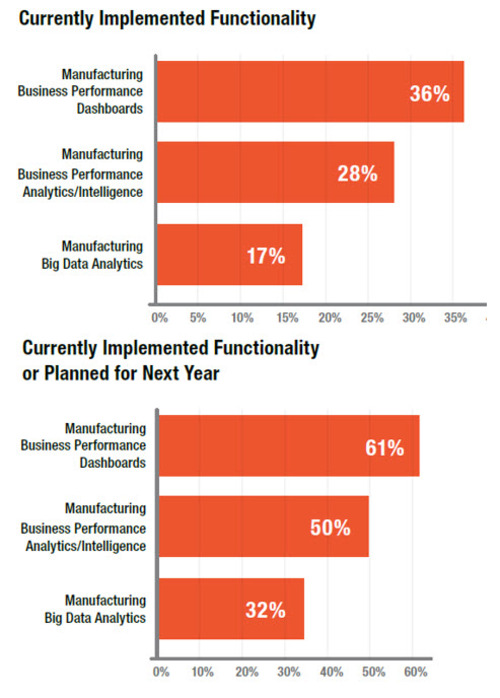

While Big Data analytical capabilities are still in their early stages, research shows that manufacturers are responding with significant interest and a forward-looking mindset. Looking at LNS Research's survey on the subject, we find that 17% of manufacturers reported currently having some type of Big Data analytics solution implemented. And looking at the next year, an additional 15% of companies surveyed plan on implementing a Big Data analytics solution.

Recommendations

While Big Data analytics capabilities are not yet a prerequisite to manufacturing success, the day where having some sort of advanced analytical capabilities in order to retain competitive advantage is not far off. Organizations with an eye for long-term success should evaluate Big Data solutions in the areas of quality management, event processing, predictive modeling, and role based dashboards. Those that do will be in the best position to compete in the coming years as Big Data capabilities progress.

For a deeper dive into the strategies that leading manufacturers are leveraging to drive benefits in Big Data analytics, download the free LNS Research report "Big Data: Driving Quality Intelligence at the Speed of Manufacturing."

Written by

Written by